A BREADTH OF EXPERTISE

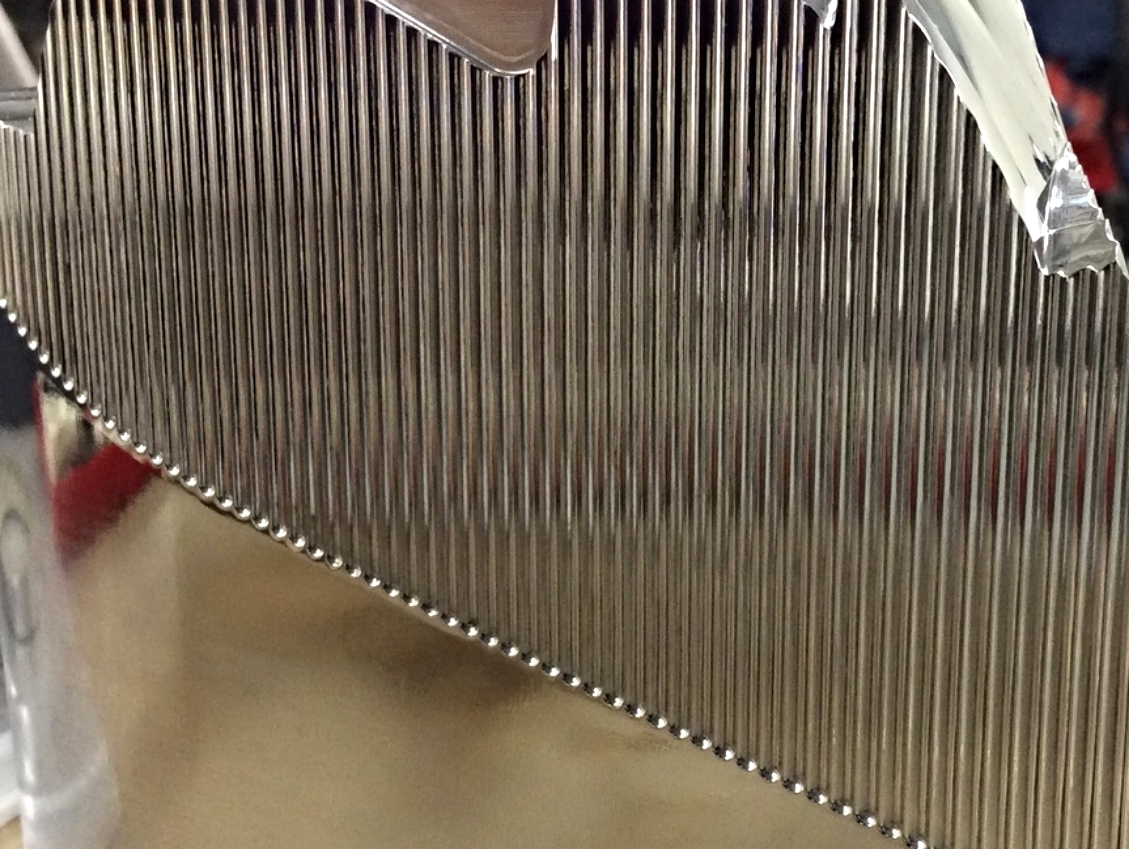

Our expertise encompasses engineered coatings such as hard chrome and electroless nickel as well as technical metal polishing to all industry standards. Applications range from the most delicate microparts to large scale industrial production tools up to 20 tons

precision plastic injection molds

automotive molds and dies

medical device and delivery system component molds

compression molds

pultrusion & extrusion dies

micro parts

precision military & aerospace fasteners

optics

MORE THAN JUST COMPETENT

Our experienced technicians share a strong background in tooling and production and are proficient in a range of coating and plating processes as well as manual polishing methods that consistently exceed industry standards. While our workshop teams typically perform project work in-house, our scope goes beyond the shop and extends to customer facilities for on-site tool maintenance and production run testing for tool verification.

ALIGNED WITH EFFICIENCY

We realize our important role as a link in many supply chains and are committed to efficiency and systematic workflow management at all scales. Like most of our supply chain partners, we utilize principles drawn from efficiency paradigms such as LEAN, Kaizen, and Six Sigma. Diligent project management ensures that project flow is consistent and efficient throughout each phase of progress. We have an affinity for the critical schedules of each customer and we are able to staff projects 24/7.

QUALITY FROM START TO FINISH

Meeting the strict industry standards and tight technical tolerances required by our customers is a baseline in the performance of our work. Although we're accustomed to meeting and exceeding these established baselines, we never consider this as simply an automatic outcome. Producing the highest quality work on a consistent day-to-day basis requires planning, diligence, continuity, and sharp focus at varying scales of detail, all enforced by a necessary sense of urgency.

Our quality control protocol goes beyond basic hardness testing and microscopic inspection. What can be seen and quantified is essential, but what can't be readily seen and quantified also becomes crucial in the process of collecting QC data. Experience, instinct, and technical proficiency are all leveraged to holistically evaluate each project component for specification conformity before leaving our facility and shipping to our customers.