DRY BLAST

Dry blast finishes are achieved using a variety of media including aluminum oxide, silica, glass bead, and shot-peening. Finishes can be controlled from 15-20 RMS up to 200-300 RMS.

SPI D DRY BLAST FINISHES

D-1 dry blast glass bead #11

D-2 dry blast #240 oxide

D-3 dry blast #24 oxide

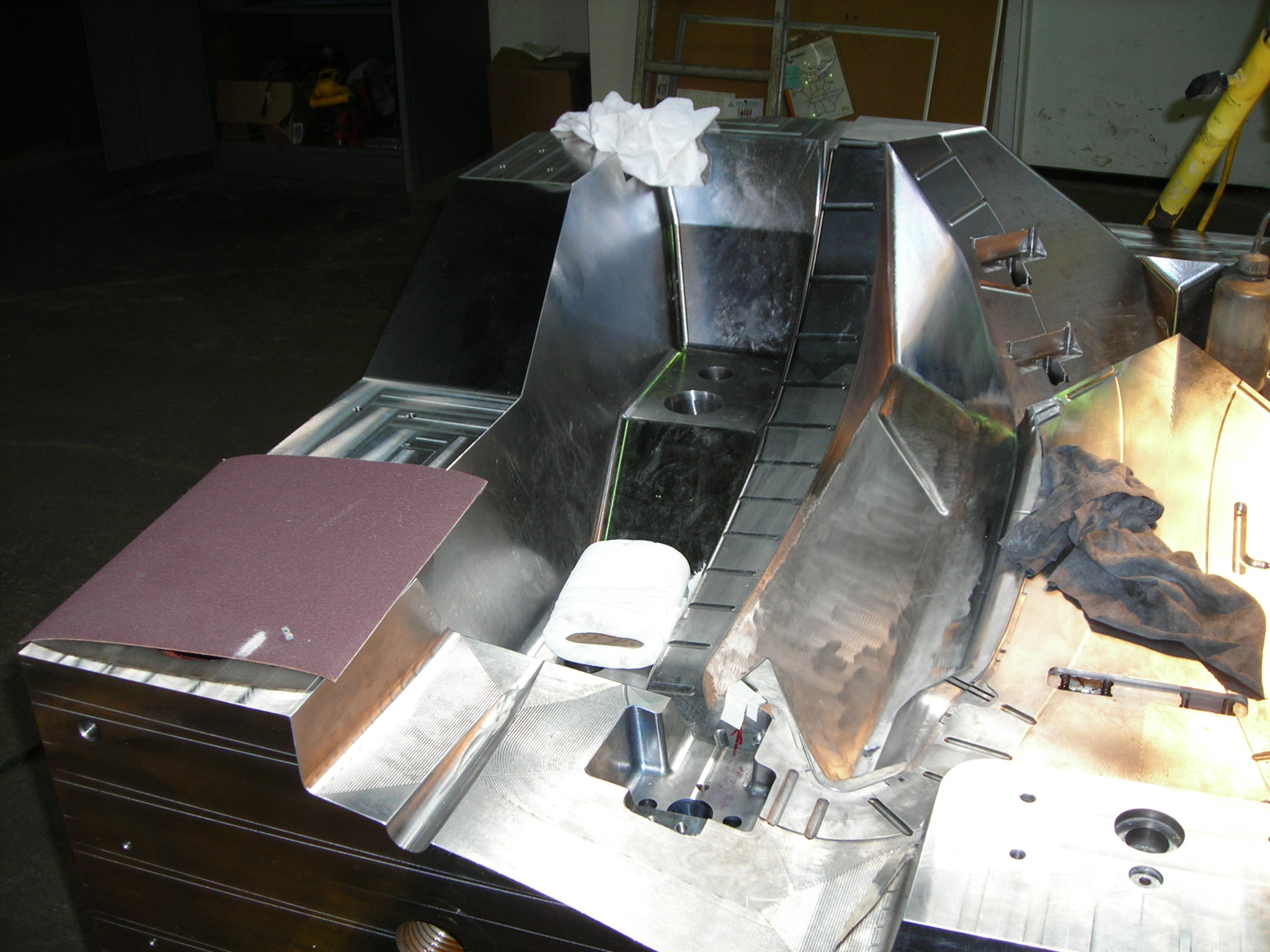

TEXTURE PREP

Pre-texture surface preparation is a vital process that ensures molding surfaces are properly prepared for the texturing process using operations such as acid testing, hardness matching, and contour verification.